Developing your first C-41 film

How to Develop Color Film at Home

Developing color film using the C-41 process at home is more challenging than developing black-and-white film, as it requires higher chemical temperatures. However, with the right tools, materials, and patience, it is definitely doable. Here’s a guide to help you develop your color film with a C-41 starter kit:

What You Need

- Film Developing Tank – Holds reels inside and allows chemicals to be poured in and out.

- Reels – Used to load your film. Ensure they’re suitable for your format (35mm, 120, 4×5, etc.).

- Darkroom or Changing Bag – To load film in complete darkness.

- Thermometer – For accurate chemical temperatures.

- Film Clips – For drying film.

- Measuring Cylinders – For mixing chemicals.

- Scissors – Needed for 35mm film trimming in the dark.

- C-41 Chemicals – Developer, Blix, and Stabilizer.

- Storage Bottles – For storing mixed chemistry.

- Distilled Water (optional) – If your tap water is mineral-rich.

- AGO Film Processor (optional) – Maintains temperature automatically.

- Sous-Vide Heater (optional) – Or use hot water in a sink.

- Timer – Not required with AGO.

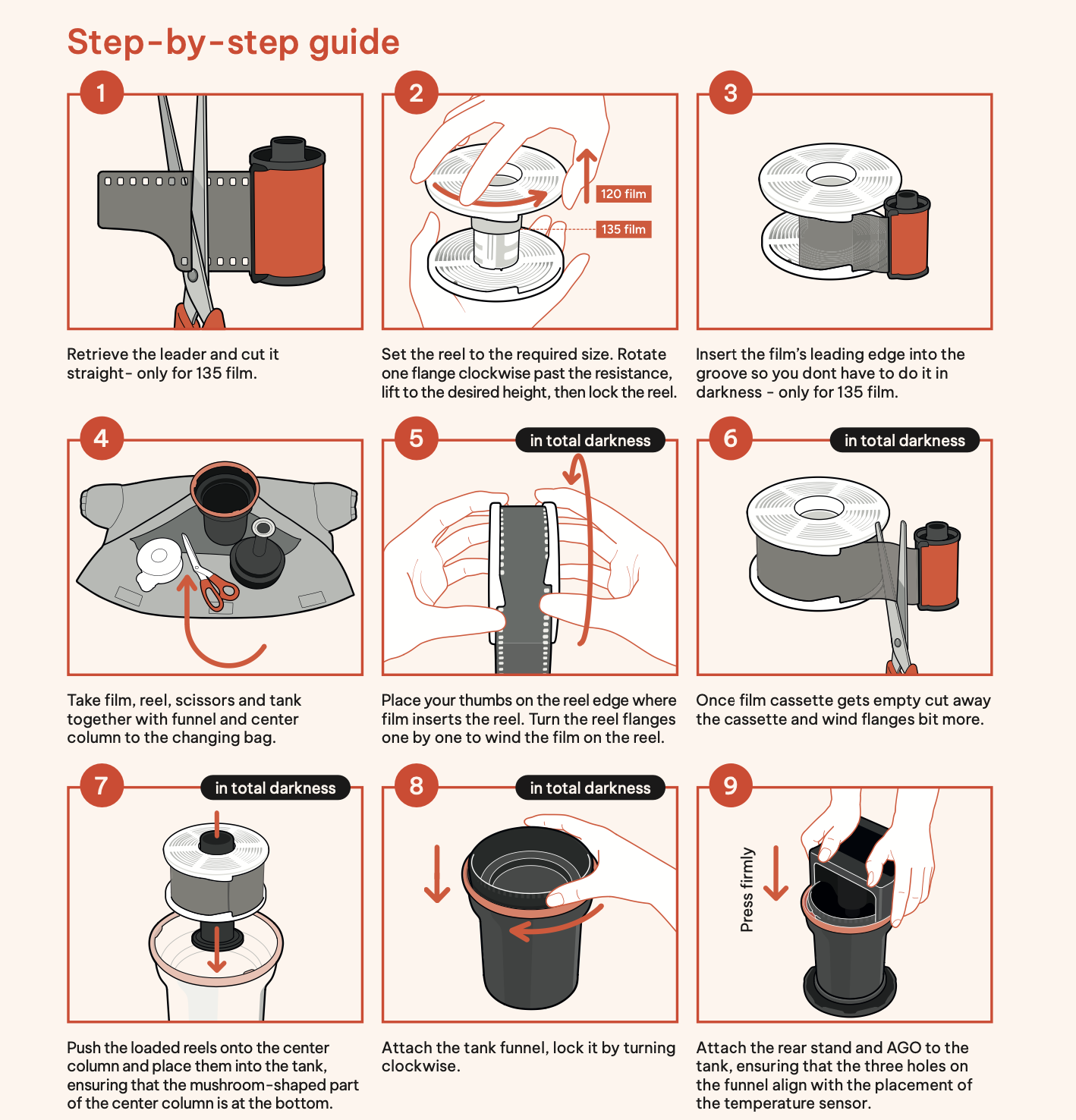

Click here to view step-by-step as images

Step-by-Step Process

- Load the Film: In complete darkness, load film onto the reel and place inside the tank.

- Prepare the Chemicals: Mix according to instructions. Heat to ~38°C (100°F), ideally 2°C higher to offset cooling.

- Developing: Follow your kit’s times and agitation instructions.

- Drying: Hang film in a dust-free space until fully dry.

- Digitize or Print: Scan negatives or make prints.

- Cut & Store: Cut into strips and place in archival sleeves.

- Store Chemicals: Keep air out of bottles to extend life.

Tips

- Volume Needed: Paterson tank: 290ml for 35mm, 500ml for 120.

- Fresh Chemicals: C-41 developer loses potency quickly; always use fresh.

- Chemical Reuse: Track rolls and adjust times if reusing.

- Temperature Control: Maintain ~38°C; AGO adjusts automatically.

- Agitation: 10 seconds initial, then 4 inversions every 30 seconds.

Troubleshooting

- Color Shifts: Incorrect temperature or exhausted chemicals.

- Streaks: Inconsistent agitation.

- Dense Negatives: Overdevelopment or wrong chemical strength.

Conclusion

With the right materials and attention to detail, developing C-41 film at home is straightforward. Keep temperatures accurate, agitate consistently, and handle film gently for best results.