Using the machine: Programs

Programs

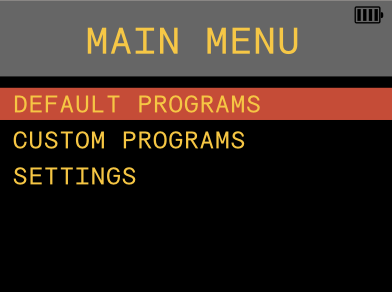

AGO has two kinds of process specific programs stored in its memory- Default programs and Custom programs. All the stored programs can be modified and all the changes will be saved.

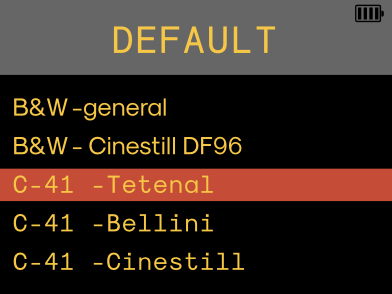

Default programs

These are standard chemistry-specific development processes to which we have been able to develop our time compensation functionality so far.

Custom programs

You can make custom programs yourself using the program configurator through the external user interface. There you can name the programs and adjust every aspect of the process. Also, you can apply our time compensation formulas to different places. Custom programs are especially useful for different B&W film-developer combinations so you don’t have to always look at the development time and adjust the program.

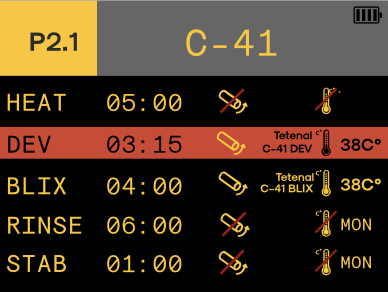

Program overview page

Here, you have the flexibility to modify each step of the process according to your preferences. Customize the time, and agitation method, and choose whether to enable time compensation or not.

If you are using time compensation and it has a specific temperature behind, you should use the corresponding time. This can be found in the chemical producer data sheet.

MON at the end of the row indicates that this step does not have time compensation but the

the system still checks if the temperature is in the range as specified in the chemical manufacturer’s data sheet.

Resetting default programs

By clicking shortly ON/OFF button on the program overview page it is possible to reset the program values to as it was initially. After asking if you want to reset this program press the FORWARD/START button to confirm it or the BACK button to decline.

Ongoing process step page

During an active process, this page provides real-time information about the ongoing processing step.

You can track:

- What chemical is in use (e.g., DEV, STOP, etc.).

- Initial time.

- Agitation method.

- Time compensation type.

- Timer.

- Compensated time.

- Temperature.

Motor

After the timer gets to zero the motor works another 15 seconds. Once this is over AGO goes automatically to the next process step.

Temperature

These steps which have time compensation or MON look if the temperature is in the right temperature range. Temperature ranges are taken from the corresponding chemical datasheet. Temperature is in the range if the background of the thermometer is gray. Once the temperature is out of the range the background goes to red.

NB! Once you are committed to the process with out-of-range chemical temperature, you should still carry on, there is a good chance that you still get sufficient results as our time compensation formulas also tries to do its best out of the suggested temperature range.

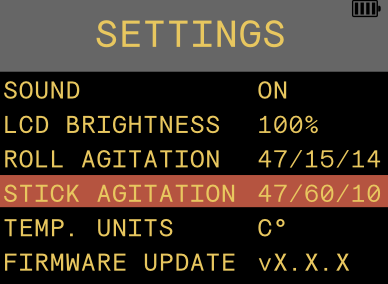

Settings menu

The settings page allows you to customize additional parameters to enhance your user experience.

- Sound: Turn on or off the notification sound

- LCD brightness: Adjust the brightness of the screen

- Roll & Stick Agitation Parameters: Fine-tune the parameters for both agitation modes.

- Temp. unit: Choose between Celsius or Fahrenheit scale.

- Firmware update: Enable Wi-Fi for firmware updates and programs configurator.

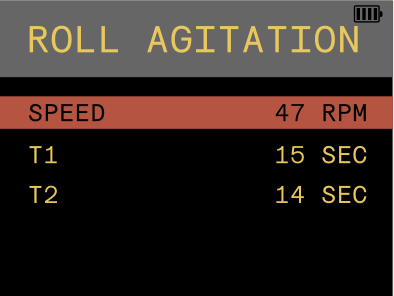

Roll Agitation

In this mode, the rotation direction inverts as specified by T1 and T2. The shaft rotates continuously until the end of the process.

- Speed: Rotation speed, measured in revolutions per minute (rpm).

- T1: Rotation time clockwise.

- T2: Rotation time counter-clockwise.

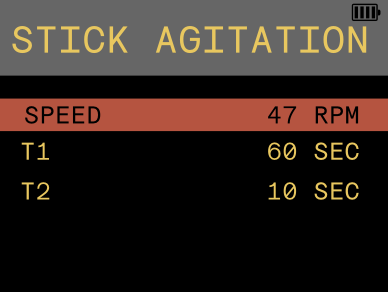

Stick Agitation

This mode involves continuous rotation for T1 duration, followed by rotation for T2 seconds every minute.

- Speed: Rotation speed, measured in revolutions per minute (rpm).

- T1: Constant rotation time after the start.

- T2: After T1, the duration of rotation every minute.

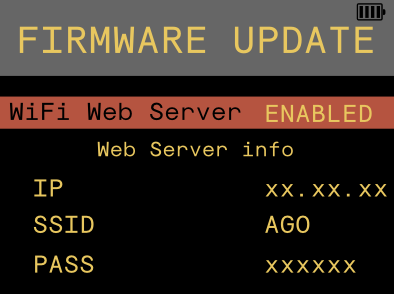

Firmware update

Once enabled it creates a WiFi router that you can access with your desktop or mobile device. After connecting with AGO go to your internet browser and type in the IP

- IP: To be used as URL in your browser

- SSID: WiFI router name

- PASS: Password to access the route

Continue on the topic of Firmware update HERE