Welcome back, its been a little while since last blog post was made but we weren’t sleeping and things have moved forwards on different fronts.

The best news for the sake of this project is that we have new person who joined the project. His name is Indur, he has quit extensive experience on coding and leading such hardware projects from developing to manufacturing. So one mechanical engineer and developer got together, this can only bring good things 🙂

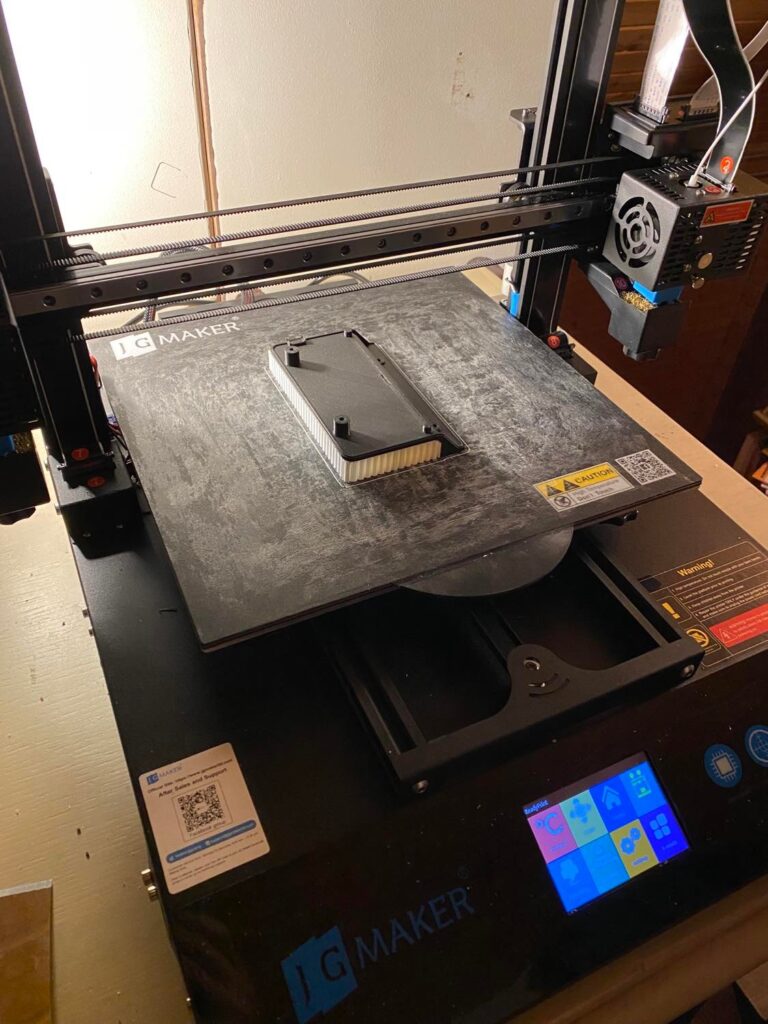

For the sake of quality second generation prototypes I bought new 3D printer. Reason I bought this JGMaker Artist D was that it is IDEX printer, meaning it has two print heads which allow to print two different materials. One of which is PLA for structure and other is support materials. So far the the results have been quit good with the Prusament Galaxy black in combination with Polymaker PolySupport filament. Foremost it gives satisfactory look for the parts, that I would dear to send to customers.

On temperature control I have started testing and widening my knowhow about it. I think I have found a good test method to validate B&W development process. For that I bought Ansel Adams – The negative, book which describes zone system and sensitometry, to measure film densities in different zones and validate exposure and development. As Ansel said you expose for darks and develop for bights, good learning for the future pictures I make and foremost determining process to test developing algorithm with different temperatures. To test it I have exposed FOMAPAN 100 with EOS 30 to different zones using PC white screen, lens in infinity. Developed with ID-11, then scanned negatives with EPSON V750 and measured densities as described here https://sites.google.com/site/negfix/scan_dens to compared them with desired values. So far with Ilford chemicals everything has been spot on, only concern is that with different chemicals like Rodinal etc. time/temperature compensation graph is different- but thid is for future testing.

Another topic is C-41 for what I haven’t found much information and mathematically compensation formula seems bit different. If you know someone to recommend to discuss about it you can let me know, it would be great help.

On last days I have been receiving parts mostly from China. Quality seems quit good and test samples arrived really fast to Estonia. It is quit surprising how much cheaper components are from there, probably wouldn’t imagine this project if I had to ordered them from Europe.

For the next steps we are concentrating on getting the prototype ready and then starting bit more the promotional work. For that main obstacle is PCB design which our Chines friend is helping us out, also PCB component supplies and manufacturing seem quit an undertaking, since there are many specific parts which can have problems with supply. After that comes coding to update it with time compensation algorithms and bit fresher user interface.

This is the progress so far, if the project seems interesting subscribe and take contact if you would like to share you experience.

Live safe

Arno